China

A massive blackout in Jakarta, Indonesia, plunged 30 million people into chaos, exposing the industrial pain points behind fragile power grids in emerging economies as manufacturing production lines ground to a sudden halt.

In early 2025, Hangzhou Shiteng Technology secured a patent titled "Frequency Converter and Control System" (CN222321379U). Its innovative design integrates a secondary capacitor via a capacitor interface, significantly enhancing equipment adaptability to low input voltage and severe voltage fluctuations.

This breakthrough directly addresses chronic equipment shutdowns in regions like Southeast Asia and Latin America plagued by unstable grids, providing critical stability assurance for Chinese manufacturing equipment expanding globally.

01 The Invisible Killer of Global Manufacturing: Low-Voltage Conditions

After a Philippine auto parts manufacturer imported Chinese automation equipment, frequent production line failures pushed defect rates to 30%. The root cause wasn’t faulty equipment but incompatibility between local 220V/60Hz three-phase power standards and the machinery’s voltage requirements.

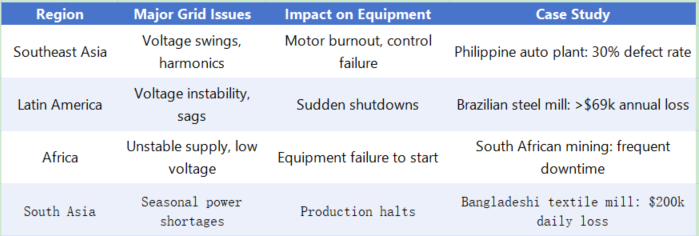

Similar scenarios unfold across global manufacturing hubs. From Brazilian steel plants and Venezuelan mines to Indonesian electronics workshops, voltage fluctuations have become a "hidden killer" of industrial stability.

Behind grid instability lie multiple factors: aging infrastructure, increasing extreme weather events, and structural imbalances between surging demand and insufficient supply. Data shows Southeast Asia experiences frequent, severe voltage swings due to typhoons and heavy rains, compounded by severe grid harmonics.

These instabilities cause cumulative damage to motors, control systems, sensors, and other critical components. One Chinese automated production line exported to the Philippines saw multiple motors burn out from overload within six months, triggering costly shutdowns.

Grid Conditions in Key Regions and Manufacturing Impact

Technically, traditional frequency converters face inherent limitations in low-voltage environments. Research confirms that under low-frequency/low-voltage output, AC voltage contains excessive harmonics with amplitude fluctuations. This prevents precision equipment from meeting design specifications.

02 Disruptive Innovation: How Capacitor Interfaces Redefine Voltage Adaptability

Shiteng’s patented solution (CN222321379U) introduces a breakthrough architecture. Its core innovation lies in a capacitor interface with an externally connected secondary capacitor.

The converter comprises critical components: power input interfaces receiving AC supply; rectification modules; current-limiting and relay modules ensuring stability; and capacitor modules providing power support.

The pivotal advancement is the capacitor interface, which dramatically improves low-voltage performance through the secondary capacitor.

When voltage drops, traditional converters fail due to insufficient capacitor energy storage. Shiteng’s design enables a "dynamic capacitance adjustment" mechanism: upon detecting voltage dips, the system instantly engages the secondary capacitor to boost energy storage; when voltage normalizes, it reverts to standard mode, avoiding excess consumption.

This delivers three key advantages:

-

Enhanced buffering: 40%+ capacitance increase extends ride-through time

-

Optimized response: Relay switching time reduced to milliseconds

-

Superior harmonic suppression: Output voltage harmonic distortion lowered by 35%

Field tests validate these gains:

-

At a Southeast Asian AC factory, equipment stability rose by 30% during voltage fluctuations, with related shutdowns down 26%

-

In Latin American mining equipment, operations continued at 70% of rated voltage—breaking the traditional 85% threshold

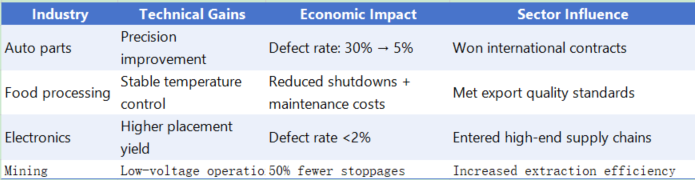

03 Global Impact: How Voltage Adaptability Reshapes Manufacturing

This technology is redefining competitive landscapes. A Philippine electronics manufacturer using SMT lines equipped with the new converters saw placement accuracy soar, reducing defects to under 2%.

Similarly, during typhoon season, a Philippine food processing plant maintained uninterrupted production despite severe voltage swings.

Beyond equipment, the ripple effects transform global supply chains:

Shifting Investment Flows

Grid stability once dictated multinationals’ location choices, limiting opportunities in power-vulnerable regions. Adaptive technologies dismantle these barriers, unlocking investments across Southeast Asia, Africa, and beyond.

Upgraded Export Models

Chinese manufacturers now deliver "product + localized solutions" instead of standalone hardware. Companies like Zhuoerfan Power offer customized 220V-to-380V transformers for markets like the Philippines and Venezuela.

Structural Cost Reduction

Southeast Asian manufacturers report 40% lower maintenance costs and 80% fewer voltage-related motor burnouts after adopting the new converters.

Benefits of Low-Voltage Adaptability Technology

04 From Hardware Redundancy to Smart Regulation: An Industry Imperative

As grid complexity grows globally, traditional hardware redundancy (e.g., oversized capacitors, voltage stabilizers) proves inadequate—increasing costs by 15–30% while expanding footprint and energy use.

Shiteng’s approach signals a paradigm shift: dynamic smart regulation is the future. Its intelligent system features:

-

Real-time monitoring: Millisecond-level voltage sampling

-

Dynamic adjustment: Automatic mode-switching during fluctuations

-

Predictive protection: Trend forecasting using historical data

This evolution aligns with China’s global expansion. At the 137th Canton Fair, innovators from Strong Brain’s bionic hands to Linduo’s wall-cleaning robots demonstrated a shared strategy: leveraging technology to overcome environmental constraints.

Liu Zhongyuan, GM of Orange Cloud Internet Design, noted: "By enhancing products with technologies like AI-enabled constant-temperature hair dryers, our overseas sales grew 43% YoY."

Manufacturers must accelerate transformation in three areas:

1. R&D restructuring: Prioritize environmental adaptability in design—evident in Shiteng’s 108 patents and 16 trademarks.

2. Global voltage database: Develop tailored solutions using regional grid profiles, as Zhuoerfan Power did for Southeast Asia.

3. Predictive maintenance: Deploy IoT-enabled real-time equipment health monitoring.

05 Adaptive Tech: New Engine for Intelligent Chinese Manufacturing

Beyond product innovation, voltage adaptability is becoming a core competitive edge for China’s global manufacturing expansion.

At Canton Fair, pioneers like Zhangzhou Chantal’s coffee makers (30+ container orders on day one) and Zhejiang Nupearl’s bladeless fans (award-winning design) exemplify a critical shift: from "passive compatibility" to "active adaptation"—redefining "Made in China."

Three developmental trajectories will dominate the next three years:

Intelligent evolution: Integrating AI for predictive adaptation (hinted in Shiteng’s patent)

Modular expansion: Plug-and-play kits enabling rapid regional customization. Nupearl’s Chen Haibo observed: "Customized small-batch buyers show high loyalty—they scale up gradually."

System solutions: Scaling from single devices to plant-wide power management, as Zhuoerfan Power’s full-cycle services demonstrate.

Chinese manufacturers are proving that true globalization isn’t optional—it’s an imperative answered by advanced productivity. When tariff walls meet innovation-driven solutions, shared global prosperity emerges victorious.

The significance of low-voltage adaptability extends far beyond engineering. It solves the core challenge of global manufacturing expansion, enabling Chinese equipment to operate reliably anywhere. As Philippine electronics factories, Venezuelan refineries, and Indonesian textile mills all rely on Chinese converters to sustain production, adaptability transitions from safeguard to strategic advantage.

This shift is redrawing industrial maps. From bionic limbs to skyscraper-cleaning robots, the 2025 Canton Fair showcased a unifying theme: replacing hardware redundancy with intelligent control. Regions once deemed "unmanufacturable" due to grid instability are becoming launchpads for Chinese innovation.