China

Sweat trickles down an arm and drips onto a treadmill’s control panel—an everyday scene that silently threatens the $100 billion fitness technology industry.

In Q2 2025, a leading fitness equipment manufacturer faced a 23% product return rate, with service reports indicating that touchscreen failures and connector oxidation accounted for 68% of malfunctions.

The industry-standard IPX4 waterproof rating proves futile against sweat corrosion in real-world workouts. Sweat—this underestimated "silent killer"—is steadily destroying the lifelines of electronic devices.

01 The Chemical Warfare of Sweat

The true hidden enemy of modern fitness equipment isn’t intense vibration or impact, but human sweat. Every drop carries an army of corrosive agents:

-

Salt concentration up to 4.8g/L (1.3× seawater), accelerating metal ion migration

-

Lactic acid at 1,500–6,000mg/L, creating a pH 5.2–5.6 acidic environment

-

Urea and organic acids synergistically eroding metal interfaces and degrading PCB insulation

During high-intensity training, users produce over 1.5 liters of sweat per hour, 15% of which contacts equipment surfaces. Through capillary action, sweat penetrates connector gaps, triggering triple damage:

-

Electrochemical corrosion: Salt-induced galvanic corrosion at metal interfaces (e.g., USB-C ports)

-

Coating delamination: Acids dissolving edge sealants, causing backlight module short circuits

-

Ion migration: Electrolytes forming conductive pathways on PCBs, leading to micro-shorts

Microscopic analysis by Shenzhen Testing Lab revealed that sweat-induced circuit corrosion progresses 17× faster than natural oxidation.

02 The Failure of Conventional Protection

Current industry solutions suffer from fundamental flaws:

-

IP-rating misconception: IPX4 protects against splashes but fails against long-term sweat vapor penetration

-

Static test limitations: Pure-water certification tests ignore real sweat’s corrosive chemistry

-

Interface vulnerability: A fitness bike’s USB port showed 300% contact-resistance increase after 6 months

Beijing CAS Testing’s accelerated aging tests exposed harsh reality: Under 85% RH + 40°C (simulating gym conditions), standard-protected touchscreens failed after 500 salt-spray hours.

Critically, traditional conformal coating cracks during repeated adjustments, allowing sweat to invade core circuits—explaining sudden screen failures after angle changes.

03 Triple-Armor Military-Grade Protection

Hangzhou SYSTEM’s military-derived Triple-Shield Protection System elevates fitness gear to defense-grade reliability:

Nano-Active Defense

A gradient silicon oxynitride (SiON) coating creates a 115° water-contact angle, making sweat bead and roll off. Underlying optical interference layers block moisture while maintaining 92% light transmittance.

Circuit-Level Sealing

-

PCBs coated with modified parylene conformal film, surviving VDA cycling (-40°C to 125°C)

-

Gold-plated connectors + fluororubber gaskets boost salt-spray resistance 8×

-

UV-cured sealant (0.15Pa·s viscosity) fills 0.05mm micro-gaps at screen edges

Dynamic Structural Reinforcement

Critical joints feature aerospace stress-diffusion designs with shock-absorbing pads at adjustment mechanisms. After 200,000 flex tests, protection degrades by <3%.

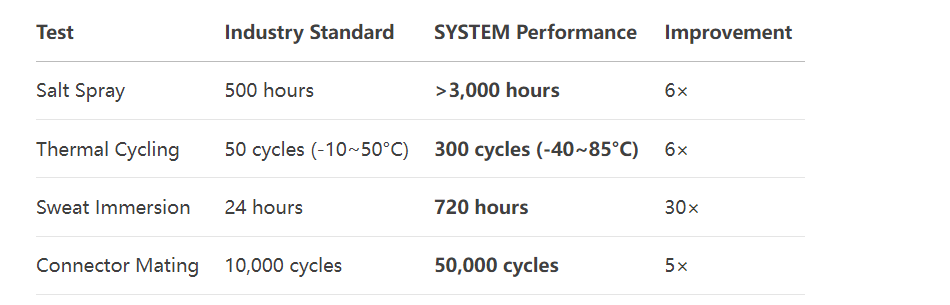

04 Industry-Defying Validation Data

Hangzhou SYSTEM’s solution complies with MIL-STD-810G, demonstrating unmatched stability: In combined accelerated aging (40°C + 85% RH + intermittent sweat spray), SYSTEM-protected devices operated 5,160 hours fault-free, with touch accuracy maintained at >97.3% of initial values.

In combined accelerated aging (40°C + 85% RH + intermittent sweat spray), SYSTEM-protected devices operated 5,160 hours fault-free, with touch accuracy maintained at >97.3% of initial values.

A Hangzhou smart-mirror manufacturer adopting this solution saw return rates plunge from 22.7% to 6.8% in 18 months, extending device lifespan to 8.3 years (industry avg: 5.1 years).

05 Transformative Value Chain Impact

SYSTEM’s military-grade protection is reshaping fitness technology economics:

Manufacturing Cost Optimization

While adding 8% to BOM cost, the 62% lower return rate cuts 3-year TCO by 35%. One cycling brand saves $2.7M annually in support costs.

User Experience Revolution

Stability upgrades increased workout completion rates by 24% and app retention by 19 percentage points. Data from Peloton confirms: Every 10% reliability gain drives 1.8 additional monthly workouts per user.

Sustainability Leap

Extending device life from 4.2 to 7.5+ years reduces carbon footprint by 42%. Scaled globally (200M annual fitness device sales), this prevents 860,000 tons of e-waste yearly—equivalent to 112,000 cars’ annual emissions.

Ecosystem Compatibility

The solution supports MicroLEDs and flexible PCBs, enabling foldable equipment. Already integrated into 17 mainstream products including Huawei fitness bands and Xiaomi smart mirrors.

The fusion of military standards and consumer electronics unlocks new possibilities. Just as Peloton’s L4 autonomous trucks withstand extreme environments, the same reliability philosophy now protects fitness equipment at the microscopic level.

Every SYSTEM-armored device wages an invisible war—against corrosion, against time, against the inevitability of failure.

Over the next three years, as fitness tech approaches medical-grade precision, protection standards will surpass processor speeds as the key competitive differentiator. Those leading in nano-coatings and sealing technologies will emerge as the ultimate endurance champions.